Our head of design looks at shoes through the centuries

As a shoemaker specifically a cycling shoemaker, there are a series of challenges we work to overcome and parameters that we must stay within. In this series I'll break down and discuss in detail these challenges and parameters, as well as some of the interesting background involved in shoe making. We’ll briefly examine a few instances from history, where shoes were first purposed for a specific task or role, and together, we’ll learn more about why we at Lake spend so much time and energy researching and creating the best cycle shoes in the world for you.

The purpose of this is to offer some clarity and explanation to the whys and how’s that are often asked from the variety of perspectives that exists with end users, retail partners and even from us here at Lake.

Part 1: The History of Industry

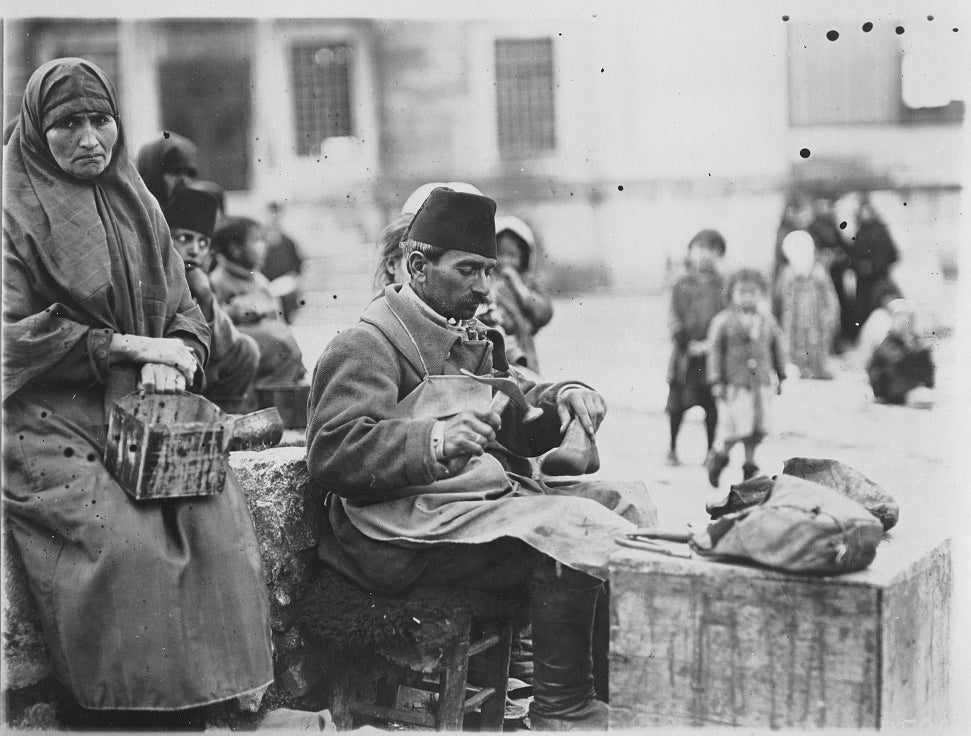

Shoe making has a long and rich history that extends over thousands of years and multiple civilizations. Historically, from the commercial perspective, people would go to a specialist/craftsman to have simple shoes hand made to fit. As shoes became more advanced and specialized, shoe making became a long, tedious, and often quite expensive process. Some hundreds of years later, we’ve somehow arrived at the mass-produced shoe making industry as we know it today; however, it really begins in the mid 18th century – that period before the industrial revolution exploded into action.

Industrialization as the world as we know it today began during this period, and many handmade crafts started to become mechanized. Deep in the Derbyshire countryside, close to our modern-day Lake shoe fitting partners at U.K. Bike Fit, Richard Arkwright created the world’s first factory system – for cloth weaving - at a riverside mill in the small village of Cromford. Powered by water, it would soon be powered by steam and the world of factory production would change, not just for shoe production, but for everything.

Many of the techniques and terms in shoe making that are commonly used today have their roots during this time of industrial revolution. Though handmade custom fit shoe making does still exist in a limited fashion today, it is far and few and often than not out of reach of most of us – and Jimmy Choo doesn'tmake cycling shoes!

These advancements in shoe making during the 18th century had multiple goals in sight to achieve. Faster production, more affordable, less labour intensive, more durability and Increase accessibility. What we consider today as simple advancements such as mechanized stitching and mechanized sole to upper assembly were quite groundbreaking and had turned shoes which were mostly reserved for the wealthy and the military into a common product that could be accessed by a larger range of people.

With even further advancements in materials and manufacturing techniques shoes became even more specialized and specific for a various number of activities and disciplines.

Shoes for Disciplines

The 20th century ushered in the next wave of technologies that even further boosted shoe making allowing shoes to be even more suited for specific uses. Whilst some limited production of shoes for specific purposes existed, such as ballet shoes, it really wasn’t until the 20th Century that need helped to speed up this process. Ultimately, it had been ad-hoc before, as with ballet shoes, where a famed dancer in the Paris Opéra Ballet, Marie Camargo, had simply snapped off the heel of her sole to make it more flexible in use – viola, the flat and soft-soled ballet shoe design was created. Back to the 20th Century then, where advancements in adhesives and mold making allowed for complex designs to be produced and assembled with greater reduction in variation and improved accuracy to the design. However, when we look at the results of those two advancements and we really dig into what that means, we start to see new parameters and barrier come up that diverge from the core reason to wear shoes; comfort/fit and protection for your feet in the discipline that you are engaged in.

Reduction in Variation from pair to pair

This consistency is often measured as proof of success, but how does it measure to the individual human? On most individuals, their left to right feet has variations and inconsistencies; now, apply that to a different person. Do the benefits of consistent mass-produced shoes out-weigh the sacrifice in fit and comfort for the individual, for the sake of accuracy to the original mold/design? In most cases it does, as shoes these days have: built in adjustability through the closure system be it tradition laces, Velcro strap or a mechanical closure; pattern working to make the upper match well against the shoe last to better fit a 3D form; multiple last shapes, widths, and sizes.

These variances are all in place and intentional, to counter each step taken for gaining consistency and accuracy, as you also need adjustability to accommodate variations. It is in some sense, a counterbalance to offset the negative side effects caused by a positive intentional effect.

Lake - Shoemaker

As a shoemaker, we want to maintain that balance without ever sacrificing the comfort, fit, protection and performance for the user – you, the cyclist. We walk a fine line between pushing advancement for the sake of “faster production, more affordable product, less labour-intensive processes, more durability and Increase accessibility.” Keeping in place all our variances is critical to our mission at Lake, as it helps us to ensure that as much as possible, we can keep fit and comfort at the forefront of what we do, allowing you to ride in comfort. Yes, our shoes are made in an industrialised arena, that had evolved and developed over the past 200 years or so, but...it’s refined here at Lake, with you, the cyclist at the heart of everything we do.

From the very first pair of Lake Cycling shoes, over 40 years ago, we’ve strived to be different. We design and create more fitting options than any other brand in the world, because we know that you all have unique feet. We’ve evolved to use the technologies and processes of the modern industrialised world, to try to retain that unique fitting feeling that we’re famous for here at Lake. Next time that you wrap your feet in our shoes, take a moment to think about how shoe making has evolved, and how special your feet feel with Lake.

Why Choose Lake Cycling Shoes

Why Choose Lake Cycling Shoes